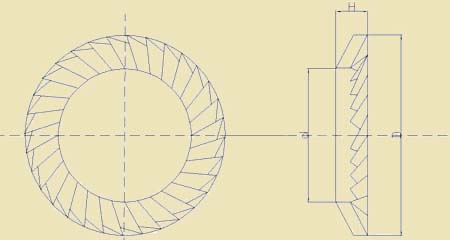

Serrated Safety Washers (anti-vibration)

Serrated safe spring washers are also named as lock washers that solve

Toothed check washer includes S series and VS series, which can be used to prevent against the looseness of bolts incurred due to vibration by increasing the frictional resistance after the connection of washer and bolt.

| 一、Standard load specifications | ||||||

| Item no. | sizes | D/mm | d/mm | t/mm | H0Max/mm | Q/kg/1000pec |

| SY9101 | M1.6 | 1.7 | 3.2 | 0.35 | 0.6 | 0.013 |

| SY9102 | M2 | 2.2 | 4 | 0.35 | 0.6 | 0.021 |

| SY9103 | M2.5 | 2.7 | 4.8 | 0.45 | 0.9 | 0.039 |

| SY9104 | M3 | 3.2 | 5.5 | 0.45 | 0.9 | 0.049 |

| SY9105 | M3.5 | 3.7 | 6 | 0.45 | 0.9 | 0.055 |

| SY9106 | M4 | 4.3 | 7 | 0.5 | 1 | 0.085 |

| SY9107 | M5 | 5.3 | 9 | 0.6 | 1.1 | 0.167 |

| SY9108 | M6 | 6.4 | 10 | 0.7 | 1.2 | 0.2 |

| SY9109 | M6.35 | 6.7 | 9.5 | 0.7 | 1.2 | 0.15 |

| SY9110 | M7 | 7.4 | 12 | 0.7 | 1.3 | 0.355 |

| SY9111 | M8 | 8.4 | 13 | 0.8 | 1.4 | 0.392 |

| SY9112 | M10 | 10.5 | 16 | 1 | 1.6 | 0.75 |

| SY9113 | M11.1 | 11.6 | 15.9 | 1 | 1.6 | 0.595 |

| SY9114 | M12 | 13 | 18 | 1.1 | 1.7 | 0.879 |

| SY9115 | M12.7 | 13.7 | 19 | 1.1 | 1.8 | 0.976 |

| SY9116 | M14 | 15 | 22 | 1.2 | 2 | 1.641 |

| SY9117 | M16 | 17 | 24 | 1.3 | 2.1 | 1.984 |

| SY9118 | M18 | 19 | 27 | 1.5 | 2.3 | 2.97 |

| SY9119 | M19 | 20 | 30 | 1.5 | 2.5 | 4.1 |

| SY9120 | M20 | 21 | 30 | 1.5 | 2.5 | 3.742 |

| SY9121 | M22 | 23 | 33 | 1.5 | 2.7 | 4.507 |

| SY9122 | M24 | 25.6 | 36 | 1.8 | 2.9 | 5.91 |

| SY9123 | M25.4 | 27 | 38 | 2 | 3.1 | 7.449 |

| SY9124 | M27 | 28.6 | 39 | 2 | 3.1 | 7.369 |

| SY9125 | M30 | 31.6 | 45 | 2 | 3.6 | 10.78 |

| SY9126 | M36 | 38 | 54 | 2.5 | 4.2 | 21.28 |

| 二、Medium load specification | ||||||

| Item no. | sizes | D/mm | d/mm | t/mm | H0Max/mm | Q/kg/1000pec |

| SY9201 | 5 | 5.3 | 9 | 1 | 1.3 | 0.273 |

| SY9202 | 6 | 6.4 | 10 | 1 | 1.4 | 0.3 |

| SY9203 | 8 | 8.4 | 13 | 1.2 | 1.7 | 0.615 |

| SY9204 | 10 | 10.5 | 16 | 1.5 | 2 | 1.167 |

| SY9205 | 12 | 13 | 18 | 1.5 | 2.1 | 1.223 |

| SY9206 | 14 | 15 | 22 | 1.5 | 2.2 | 2.089 |

| SY9207 | 16 | 17 | 24 | 2 | 2.6 | 3.142 |

| SY9208 | 18 | 19 | 27 | 2 | 2.7 | 4.041 |

| SY9209 | 20 | 21 | 30 | 2 | 2.8 | 5.066 |

| SY9210 | 22 | 23 | 33 | 2 | 3 | 6.117 |

| SY9211 | 24 | 25.6 | 36 | 2.5 | 3.4 | 8.865 |

| SY9212 | 27 | 28.6 | 39 | 2.5 | 3.5 | 9.731 |

| SY9213 | 30 | 31.6 | 45 | 2.5 | 3.8 | 14.38 |