Heavy Duty Bolting Washers DIN 6796

DIN 6796 high-duty safe spring washers (HDS series) are designed for the connection of bolts.

HDS series are very useful for large bearing load and good elasticity resumption. The tension of bolt is able to endure the relaxation due to following: abrasion, deformation, relaxation, expansion due to heat, or shrinkage of wearing parts, or pressing of sealing parts. HDS series greatly increase the elasticity of bolts, can effectively substitute for conventional spring washers, but not suitable for combinations of locking washers or flat washers.

HDS series of disc springs are applicable in an opposition or superposition combination. The opposition combination is able to increase the deformation of the pair of disc springs, while the superposition combination is able to increase the tension of the pair of disc springs. It's better that they are pressed to flatness in assembly because this status will increase the tension moment, and then an appropriate bolt tension may be obtained without a torque wrench.

| Item no. | Used for | D/mm | d/mm | t/mm | Hmax/mm | Hmin/mm | F/N | Weight per 1000pcs |

| SY401 | M2 | 5 | 2.2 | 0.4 | 0.6 | 0.5 | 630 | 0.05 |

| SY402 | M2.5 | 6 | 2.7 | 0.5 | 0.72 | 0.61 | 950 | 0.09 |

| SY403 | M3 | 7 | 3.2 | 0.6 | 0.85 | 0.72 | 1320 | 0.14 |

| SY404 | M3.5 | 8 | 3.7 | 0.8 | 1.06 | 0.92 | 2400 | 0.25 |

| SY405 | M4 | 9 | 4.3 | 1 | 1.3 | 1.12 | 3800 | 0.38 |

| SY406 | M5 | 11 | 5.3 | 1.2 | 1.55 | 1.35 | 5500 | 0.68 |

| SY407 | M6 | 14 | 6.4 | 1.5 | 2 | 1.7 | 8600 | 1.42 |

| SY408 | M7 | 17 | 7.4 | 1.75 | 2.3 | 2 | 11300 | 2.51 |

| SY409 | M8 | 18 | 8.4 | 2 | 2.6 | 2.24 | 14900 | 3.1 |

| SY410 | M10 | 23 | 10.5 | 2.5 | 3.2 | 2.8 | 22100 | 5.13 |

| SY411 | M12 | 29 | 13 | 3 | 3.95 | 3.43 | 34100 | 12.35 |

| SY412 | M14 | 35 | 15 | 3.5 | 4.65 | 4.04 | 46000 | 21.44 |

| SY413 | M16 | 39 | 17 | 4 | 5.25 | 4.58 | 59700 | 30.19 |

| SY414 | M18 | 42 | 19 | 4.5 | 5.8 | 5.08 | 74400 | 38.68 |

| SY415 | M20 | 45 | 21 | 5 | 6.4 | 5.6 | 93200 | 48.52 |

| SY416 | M22 | 49 | 23 | 5.5 | 7.05 | 6.15 | 114000 | 63.07 |

| SY417 | M24 | 56 | 25 | 6 | 7.75 | 6.77 | 131000 | 92.3 |

| SY418 | M27 | 60 | 28 | 6.5 | 8.35 | 7.3 | 154000 | 112.13 |

| SY419 | M30 | 70 | 31 | 7 | 9.2 | 8 | 172000 | 168.92 |

| SY420 | M33 | 76 | 34 | 7.5 | 10 | 8.5 | 226000 | 213.52 |

| SY421 | M36 | 83 | 37.2 | 8 | 10.5 | 9.2 | 276000 | 271.39 |

| SY422 | M42 | 96 | 43.5 | 8.5 | 12 | 10.5 | 290000 | 383.61 |

| SY423 | M48 | 110 | 49.5 | 9 | 12.5 | 11 | 261000 | 535.18 |

| SY424 | M56 | 128 | 58 | 9.5 | 13.5 | 12 | 260000 | 762.21 |

| SY425 | M64 | 136 | 66 | 10 | 14 | 12.8 | 277000 | 871.34 |

| SY426 | M72 | 145 | 74 | 10.5 | 15 | 13 | 327000 | 1006.08 |

| SY427 | M90 | 160 | 92.5 | 11 | 16 | 14 | 378000 | 1155.31 |

| SY428 | M100 | 180 | 102.5 | 11.5 | 17 | 15 | 370000 | 1551.52 |

| SY429 | M125 | 220 | 128 | 12 | 19 | 16.5 | 365000 | 2367.49 |

SPRING WASHERS ASSEMBLY

spring washer is made up of three or four smooth, inseparably assembled tapered spring washers.

They are made in heat-treated carbon steel or stainless steel.

They are available for all bolt sizes and support all finishes, depending on the anti-corrosion requirements.

functions

Spring washer maintains a high level of tension in the screw while conserving considerable elastic energy stored in a small volume.

This washer guarantees that the assembly will not loosen in the event of crushing, material expansion, wear or vibration. It compensates for expansion gaps and its elasticity maintains optimal tension in the screws and bolted assembly.

Principal functions:

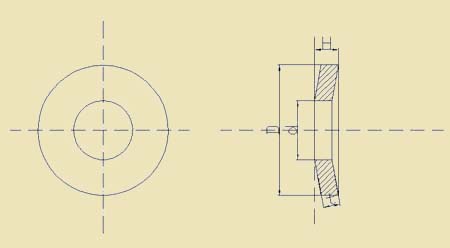

Dimensions |

|

Type 3L

Type 4L